FOOT STEP POWER GENERATOR FOR MOBILE CHARGING

CHAPTER

1

INTRODUCTION

1.1 Project Introduction -

Energy

is nothing but the ability to do work. Power has turned into help for the human

populace nowadays. Its request is expanding rapidly. In day to day, life

innovation needs an immense measure of electrical power for its different

activities. Power generation is the single largest wellspring of contamination

in the world. Due to which numerous energy resources are produced and wasted.

Electricity is generally generated from resources like water, wind, coal, etc.

for generating the electricity from these resources development of big plants

that are needed having high maintenance and high cost. In like manner, it is

the target of the present development to give the technique for electrical

power generation from which regularly expanding human populace that does not

adversely affect the natural resources. Our project depends on a rule called

the piezoelectric effect impact, in which certain materials can develop an

electrical charge from having weight, the strain applied to them. The

piezoelectric effect is the effect of specific materials to generate the

electric charge in response to applied mechanical stress on it. It is the

effect in which mechanical vibrations, pressure or strain applied to the

piezoelectric material are converted into electrical form. Piezoelectricity

alludes to the capacity of a few materials to produce an electric potential in

light of connected weight. The inserted piezoelectric material can give the

enchantment of the changing overweight applied by moving individuals into the

electric current, which is stored in a battery and further distributed using

RFID cards. The current is distributed using (radio-frequency identification)

RFID cards so that only an authorized person can use the generator for

charging. Thus we charge a battery using power from footsteps, display it on

LCD using a microcontroller circuit and allow for mobile charging through the

setup. Our project model cost is effective and easy to implement and also it is

green and not harmful to the environment.

CHAPTER

NO.2

2.

BLOCK DIAGRAM& EXPLAINATION

Fig- 2Block diagram

The following figure shows the block diagram of an footstep power generator using RFID for charging. After applying weight on piezoelectric plates voltage is developed across the plates. That voltage is applied to the battery for charging purposes. This is then provided to our monitoring circuitry.LCD is interfaced with a piezo sensor using a microcontroller that allows the user to monitor the voltage and charges a connected battery by it. Also,it consists of a USB mobile phone charging point where the user may connect cables to charge the mobile phone from the battery charge.

The block diagram consists of following parts-

2.1

MICROCONTROLLER –

Microcontroller ATmega328 is an 8-bit and 28 Pins AVR Microcontroller, manufactured by Microchip, follows RISC Architecure and has

a flash type program memory of 32KB.It has an EEPROM memory of 1KB and its SRAM

memory is of 2KB. It is mostly used in arudino uno. The microcontroller which

is used to monitors the voltage that charges the rechargeable battery. It then,

displays the amount of charging on the LCD. The microcontroller also helps

controlling charging and discharging of the battery to protect it from over

charging and avoiding the damage could be caused.

Fig-2.1.1 Microcontroller

2.2 PIEZOELECTRIC

SENSOR-

The Piezo electrical sensors are placed under insulating

material (platform) and pressure is created by footstep. The property of

piezoelectric material is to generate electricity when we apply pressure. It

gives an amount of output voltage that varies than the other when pressure is

applied.These sensors are mainly used for process control, quality assurance,

research and development in various industries. The applications of this sensor

involve, aerospace, medical, nuclear instrumentation, and as a pressure sensor

it is used in the touch pad of mobile phones.

Fig-2.2.1 Piezoelectric sensor

2.3 BATTERY

Battery (electricity), an array of electrochemical cells for

electricity storage, either individually linked or individually linked and

housed in a single unit. An electrical battery is a combination of one or more electrochemical

cells, used to convert stored chemical energy into electrical energy. Batteries

may be used once and discarded, or recharged for years as in standby power

applications.Lead-acid batteries are the most common in PV systems because

their initial cost is lower. Lead acid batteries are reliable and cost

effective with an exceptionally long life. The Lead acid batteries have high

reliability because of their ability to withstand overcharge, over discharge

vibration and shock. The use of special sealing techniques ensures that our

batteries are leak proof and non-spoilable. The batteries have exceptional

charge acceptance, large.The system battery consists of electrochemical cells

to store electricity in a single unit. Some batteries are used once and some of

them are rechargeable. Here we need a rechargeable one to be able to charge it

again when it's empty after consuming it by users.

Fig –

2.3.1 Battery

2.4 VOLTAGE

SAMPLER-

Voltage Sampler or sample and hold circuit is an essential

analog building block and the applications of voltage sampler includes switched

capacitor filters and analog-to-digital converters. The main function of the

sample and hold circuit is to sample an analog i/p signal and hold this value

over a particular length of time for subsequent processing. Sample and hold

circuit is designed using only one capacitor and one MOS transistor. The

working of this circuit is straight forward. When CK is high, then the MOS

switch will be ON, which in turn permits output voltage to track input voltage.

When CK low, then the MOS switch will be OFF.

Fig -

2.4.1 Voltage Sampler

2.5 LCD DISPLAY-

There are many choices for LCD like: 2x40 without

backlighting, 1x16 which has only one row to show and finally 2x16 which is the

most common type that can cover the system needs in very simple way. The LCD is

interfaced with the microcontroller to display the battery voltages and the

number of steps.

Fig –

2.5.1 Lcd Display

2.6 POWER SUPPLY-

Here we are using an adapter of 12Vand 1A as a power supply

to turn on the system.This adapter contains a transformer to convert the mains

electricity voltage (220V) to a lower voltage (12V), a rectifier to convert it

to pulsating DC, and a filter to smooth the pulsating waveform to DC, with

residual ripple variations small enough to leave the powered device unaffected.

CHAPTER NO.3

3. CIRCUIT DIAGRAM

Fig-3.1

Circuit Diagram

The

schematic diagram is shown in above figure. A tile made up of piezo material generates

voltage across a piezo tile which is supplied to a bridge rectifier circuit to

obtained DC voltage and given to a rechargeable battery and thus the battery

gets charged and this can be used to drive DC loads. The battery used here is a

Lead Acid Battery of 6V. A LCD is interfaced with microcontroller. The

microcontroller used here is ATMEGA 328P which is 8-bit,32kb flash with 1k RAM

and has 16MHz speed. The 16 x 2 LCD is used to display the voltage generated by

the piezo-electric tile. The crystal oscillator is connected to microcontroller

which is used to give clock signal. The power supply unit is used to supply

power to microcontroller and LCD. This unit consist of an IC called IC7805

which will convert the 12V to 5V.

CHAPTER NO. 4

4.

COMPONENT DESCRIPTION

4.1 MICRO CONTROLLER:

The ATmega328 is

a single-chip microcontroller created by Atmel in

the megaAVR family (later Microchip Technology acquired

Atmel in 2016). It has a modified Harvard

architecture 8-bit RISC processor core.

An ATMega Microcontroller is an 8-bit microcontroller with

Reduced Instruction Set (RISC) based Harvard Architecture. God to know: As the

name suggest, for instance, “ATmega16″ , where AT = Atmel, mega = mega AVR and

16= 16kb flash memory.

SPECIFICATIONS

OF ATMEGA MICROCONTROLLER:

The Atmel 8-bit AVR RISC-based microcontroller

combines 32 KB ISP flash memory with read-while-write

capabilities, 1 KB EEPROM, 2 KB SRAM, 23 general purpose

I/O lines, 32 general purpose working registers, three flexible

timer/counters with compare modes, internal and external interrupts,

serial programmable USART, a byte-oriented 2-wire serial

interface, SPI serial port, 6-channel 10-bit A/D

converter (8-channels in TQFP and QFN/MLF packages),

programmable watchdog timer with internal oscillator, and five

software selectable power saving modes. The device operates between 1.8-5.5

volts. The device achieves throughput approaching 1 MIPS per MHz

4.2

PIEZOELECTRIC SENSORS:

A piezoelectric

sensor is a device that uses the piezoelectric effect to

measure changes

in pressure, acceleration, temperature, strain,

or force by converting them to an electrical charge. The

prefix piezo- is Greek for 'press' or 'squeeze'.

PRINCIPLE

OF OPERATION:

The way a piezoelectric material is cut defines one of

its three main operational modes:

·

Transverse

·

Longitudinal

·

Shear.

TRANSVERSE EFFECT

A

force applied along a neutral axis (y) displaces charges along the (x)

direction, perpendicular to the line of force. The amount of charge depends on the geometrical dimensions

of the respective piezoelectric element. When dimensions apply,where is the dimension in line

with the neutral axis, is

in line with the charge generating axis and is the corresponding piezoelectric

coefficient.

LONGITUDINAL EFFECT

The

amount of charge displaced is strictly proportional to the applied force and

independent of the piezoelectric element size and shape. Putting several elements

mechanically in series and electrically in parallel is

the only way to increase the charge output. The resulting charge iswhere is the piezoelectric

coefficient for a charge in x-direction released by forces applied along

x-direction(in pC/N). is the applied Force in

x-direction [N] and corresponds

to the number of stacked elements.

SHEAR EFFECT

The

charge produced is exactly proportional to the applied force and is generated

at a right angle to the force. The charge is independent of the element size

and shape. For elements

mechanically in series and electrically in parallel the charge isIn contrast to the longitudinal and shear

effects, the transverse effect make it possible to fine-tune sensitivity on the

applied force and element dimension.

How

Do Piezoelectric Sensors Work?

Piezoelectric sensors work on the principle of

piezoelectric effect. Piezoelectric originates from the Greek word piezein,

which literally means to squeeze or press. As the latter suggests, we are

squeezing quartz crystals to make an electric voltage. Hence, piezoelectric

sensors work by applying mechanical energy to a crystal in the following steps:

1. A piezoelectric crystal is placed between two metal plates

which are normally in a perfect balance (even if they’re not symmetrically arranged) and does not

conduct any electric current.

2. Mechanical stress or force are applied on

the material by the metal plates, which forces the electric charges within the

crystal out of balance. Excess negative and positive charges appear on opposite

sides of the crystal face.

3. The metal plate collects these charges,

which can be used to produce a voltage and send an electrical current through a

circuit – transforming to piezoelectricity.

It is important to understand the behaviour of

the piezoelectric crystals when determining the piezoelectric effect.

Piezoelectric Sensors based on the piezoelectric effect can operate from

transverse, longitudinal, or shear forces, and are insensitive to electric

fields and electromagnetic radiation. The response is also very linear over

wide temperature ranges, making it an ideal sensor for rugged environments.

Piezoelectric sensors have several benefits

such as:

1. They offer very high frequency response that

means the parameter changing at very rapidly can be sensed easily.

2. High transient response as they are able to

detect the events of microseconds and also give the linear output.

3. They offer a high output that be measured in

the electronic circuit.

4. They have small dimensions and have rugged

construction which means they are easy to handle.

Fig-4.2.1 Peizo Electric Sensor

4.3 LCD

DISPLAY:

A liquid crystal display or LCD draws its definition from its

name itself. It is a combination of two states of matter, the solid and the

liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal

displays are super-thin technology display screens that are generally used in

laptop computer screens, TVs, cell phones, and portable video games.

Types of LCDs include:

Twisted Nematic (TN) -

which are inexpensive while having high response times. However, TN displays

have low contrast ratios, viewing angles and color contrasts.

In Panel Switching

displays (IPS Panels) - which boast much better contrast ratios, viewing angles

and color contrast when compared to TN LCDs.

Vertical Alignment

Panels (VA Panels) - which are seen as a medium quality between TN and IPS

displays.

Advanced Fringe Field

Switching (AFFS) - which is a top performer compared IPS displays in color

reproduction range.

4.4 LED (LIGHT-EMITTING DIODE)-

LED’s: A light-emitting diode (LED) is a two-lead semiconductor light source. It is a p–n junction diode that emits light when activated. When a suitable voltage is applied to the leads, electrons are able to recombine with electron holes within the device, releasing energy in the form of photons. This effect is called electroluminescence, and the color of the light (corresponding to the energy of the photon) is determined by the energy band gap of the semiconductor. LEDs are typically small (less than 1 mm2) and integrated optical components may be used to shape the radiation pattern.

4.5

BREAD BOARD

A breadboard is a construction base for prototyping of electronics. Originally it was literally a bread board, a polished piece of wood used for slicing bread. In the 1970s the solderless breadboard (AKA plugboard, a terminal array board) became available and nowadays the term "breadboard" is commonly used to refer to these. Because the solderless breadboard does not require soldering, it is reusable. This makes it easy to use for creating temporary prototypes and experimenting with circuit design. For this reason, solderless breadboards are also extremely popular with students and in technological education. Older breadboard types did not have this property. A stripboard (Veroboard) and similar prototyping printed circuit boards, which are used to build semi-permanent soldered prototypes or one-offs, cannot easily be reused. A variety of electronic systems may be prototyped by using breadboards, from small analog and digital circuits to complete central processing units (CPUs). Breadboard & PCB.

4.6

DIODE:

In electronics, a diode is a two-terminal electronic component that conducts primarily in one direction (asymmetric conductance); it has low (ideally zero) resistance to the current in one direction, and high (ideally infinite) resistance in the other. A semiconductor diode, the most common type today, is a crystalline piece of semiconductor material with a p–n junction connected to two electrical terminals. A vacuum tube diode has two electrodes, a plate (anode) and a heated cathode. Semiconductor diodes were the first semiconductor electronic devices. The discovery of crystals' rectifying abilities was made by German physicist Ferdinand Braun in 1874. The first semiconductor diodes, called cat's whiskerdiodes, developed around 1906, were made of mineral crystals such as galena. Today, most diodes are the most common function of a diode is to allow an electric current to pass in one direction (called the diode's forward direction), while blocking current in the opposite direction (the reverse direction). Thus, the diode can be viewed as an electronic version of a check valve. This unidirectional behavior is called rectification, and is used to convert alternating current (AC) to direct current (DC), including extraction of modulation from radio signals in radio receivers—these diodes are forms of rectifiers. Made of silicon, but other semiconductors such as selenium and germanium are sometimes used. A Rectifier Diodes IN4007 which are used in circuit.

4.7RESISTORS

The

resistor is a passive electrical component to create resistance in the flow of

electric current. In almost all electrical networks and electronic circuits

they can be found. The resistance is measured in ohms. An ohm is the resistance

that occurs when a current of one ampere passes through a resistor with a one

volt drop across its terminals. The current is proportional to the voltage

across the terminal ends. This ratio is represented by Ohm’s law:

Formula

with ohm's law: R=V/I

Resistors

are used for many purposes. A few examples include delimit electric current,

voltage division, heat generation, matching and loading circuits, control gain,

and fix time constants. They are commercially available with resistance values

over a range of more than nine orders of magnitude. They can be used to as

electric brakes to dissipate kinetic energy from trains, or be smaller than a

square millimeter for electronics.

A resistor is a

passive electrical component with the primary function to limit the flow of

electric current.

4.8

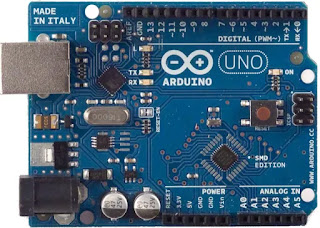

ARDIUNO UNO

The

Arduino Uno is one kind of microcontroller board based on ATmega328, and Uno is

an Italian term which means one. Arduino Uno is named for marking the upcoming

release of microcontroller board namely Arduino Uno Board 1.0. This board

includes digital I/O pins-14, a power jack, analog i/ps-6, ceramic

resonator-A16 MHz, a USB connection, an RST button, and an ICSP header. All

these can support the microcontroller for further operation by connecting this

board to the computer. The power supply of this board can be done with the help

of an AC to DC adapter, a USB cable, otherwise a battery.

What is Arduino Uno ATmega328?

The

ATmega328 is one kind of single-chip microcontroller formed with Atmel within

the megaAVR family. The architecture of this Arduino Uno is a customized

Harvard architecture with 8 bit RISC processor core. Other boards of Arduino

Uno include Arduino Pro Mini, Arduino Nano, Arduino Due, Arduino Mega, and

Arduino Leonardo

Fig-

4.7.1 Arduino Uno

Features of Arduino Uno Board

The

features of Arduino Uno ATmega328 include the following.

1.

The operating voltage is 5V

2.

The recommended input voltage will range from 7v to 12V

3.

The input voltage ranges from 6v to 20V

4.

Digital input/output pins are 14

5.

Analog i/p pins are 6

6.

DC Current for each input/output pin is 40 mA

7.

DC Current for 3.3V Pin is 50 mA

8.

Flash Memory is 32 KB

9.

SRAM is 2 KB

10.

EEPROM is 1 KB

11.

CLK Speed is 16 MHz

Arduino Uno Pin Diagram

The

Arduino Uno board can be built with power pins, analog pins, ATmegs328, ICSP

header, Reset button, power LED, digital pins, test led 13, TX/RX pins, USB

interface, an external power supply. The Arduino UNO board description is

discussed below.

Fig-

4.7.2 Arduino Uno Pin Diagram

Table no-1 Pin description

How to Use an Arduino Uno?

Arduino

Uno can detect the surroundings from the input. Here the input is a variety of

sensors and these can affect its surroundings through controlling motors,

lights, other actuators, etc. The ATmega328 microcontroller on the Arduino

board can be programmed with the help of an Arduino programming language and

the IDE (Integrated Development Environment). Arduino projects can communicate

by software while running on a PC.

Arduino Programming

Once

the Arduino IDE tool is installed in the PC, attach the Arduino board to the

computer with the help of USB cable.

Open the Arduino IDE & select the right board by choosing

Tools–>Board..>Arduino Uno, and select the right Port by choosing

Tools–>Port. This board can be programmed with the help of an Arduino

programming language depends on Wiring.

To

activate the Arduino board & flash the LED on the board, dump the program

code with the selection of Files–> Examples..>Basics..>Flash. When the

programming codes are dumped into the IDE, and then click the button ‘upload’

on the top bar. Once this process is completed, check the LED flash on the

board.

High Voltage Protection of USB

The

Arduino Uno board has a rearrangeable poly fuse that defends the USB port of

the PC from the over-voltage. Though most of the PCs have their own inner

protection, the fuse gives an additional coating of safety. If above 500mA is

given to the USB port, then the fuse will routinely crack the connection until

the over-voltage is removed.

Physical Characteristics

The

physical characteristics of an Arduino board mainly include length and width.

The printed circuit board of the Arduino Uno length and width are 2.7 X 2.1

inches, but the power jack and the USB connector will extend beyond the

previous measurement. The board can be attached on the surface otherwise case

with the screw holes.

Applications of Arduino Uno

ATmega328

The

applications of Arduino Uno include the following.

1.

Arduino Uno is used in Do-it-Yourself projects prototyping.

2.

In developing projects based on code-based control

3.

Development of Automation System

4.

Designing of basic circuit designs.

CHAPTER

NO.5

5.

SOFTWARE

In

order to program the Atmel microcontroller we will need an IDE (Integrated

Development Environment), where the programming takes place. A compiler, where our

program gets converted into MCU readable form called HEX files. An IPE

(Integrated Programming Environment), which is used to dump our hex file into

our MCUs.

1.Keil

µ vision: Keil development tools for the 8051 Microcontroller Architecture

support every level of software developer from the professional applications

engineer to the student just learning about embedded software development. When

starting a new project, simply select the microcontroller you use from the

Device Database and the µVision IDE sets all compiler, assembler, linker, and

memory options for you. Numerous example programs are included to help you get

started with the most popular embedded 8051 devices. TheKeilµVision Debugger

accurately simulates on-chip peripherals (I²C, CAN, UART, SPI, Interrupts, I/O

Ports, A/D Converter, D/A Converter, and PWM Modules) of your 8051 device.

Simulation

helps you understand hardware configurations and avoids time wasted on setup

problems. Additionally, with simulation, you can write and test applications

before target hardware is available. When you are ready to begin testing your

software application with target hardware, use the MON51, MON390, MONADI, or

FlashMON51 Target Monitors, the ISD51 In-System Debugger, or the ULINK USB-JTAG

Adapter to download and test program code on your target system.

2. Embedded

C: Embedded C is most popular programming language in software field for

developing electronic gadgets. Each processor used in electronic system is

associated with embedded software.

Embedded

C programming plays a key role in performing specific function by the

processor. In day- to-day life we used many electronic devices such as mobile

phone, washing machine, digital camera, etc. These all device working is based

on microcontroller that are programmed by embedded C

3. ISPProgrammer: Burn a Program in the Microcontroller is the process of transferring a program code to the microcontrollers memory from a compiler software. Generally, this microcontroller program is written in assembly or embedded C language. And this code is converted into hex file using Kiel IDE software, which is then transferred to the microcontroller memory using burner hardware along with dedicated software. Once the code is stored in the microcontroller, its function remains in accordance

5.1 FLOWCHART

5.2 SOURCE CODE:

//

include the library code:

#include

<LiquidCrystal.h>

//

initialize the library by associating any needed LCD interface pin

//

with the arduino pin number it is connected to

constintrs

= 2, en = 3, d4 = 4, d5 = 5, d6 = 6, d7 = 7;

LiquidCrystallcd(rs, en, d4, d5, d6, d7);

//required

variables

intprev=0,stepCount

= 0;

unsigned

long previousMillis = 0;

const

long interval = 1000;//

unsigned long currentMillis;

floatv,vout,vin;//variabls for calculating voltage

void

setup() {

pinMode(8,OUTPUT);//led

indication

//lcd code

lcd.begin(16,

2);

lcd.print("FOOT

STEP POWER");

lcd.setCursor(0,1);

lcd.print(" GENERATOR");

delay(2000);

lcd.clear();

lcd.setCursor(0,0);

lcd.print("STEP

COUNT:");

lcd.setCursor(0,1);

lcd.print("VOLTAGE:");

}

void

loop() {

v

= analogRead(A0);//analog value from voltage divider circuit

currentMillis

= millis();//calculating time

if(v!=0

and (prev == 0))

{

stepCount

+= 1; // calculating steps

digitalWrite(8,HIGH);

//led indication

lcd.setCursor(12,0);

lcd.print(stepCount);

}

else

{

if

(currentMillis - previousMillis>= 400)

{

previousMillis

= currentMillis; //time in milliseconds

digitalWrite(8,

LOW);

}

}

prev

= v;

lcd.setCursor(10,1);

//calculation

of voltage

vout

= (v*5.00)/1024.00;

vin

= vout/0.040909;

lcd.print(vin);

lcd.print("v

");

delay(200);

}

CHAPTER

NO.6

6.

APPLICATION AND FUTURE SCOPE

6.1 APPLICATIONS –

1.

Can be broadly utilized as the part of colleges, Schools, public transport

places and universities.

2.

This can be actualized in air terminals, transport stations, railroad stations.

3.

Street lights can be actualized utilizing this strategy instead of solar in the

rainy season.

4.

This framework can be actualized in swarmed places like shopping centers,

pathways and so forth.

5. It can be used in emergency power failure

situations.

6.

Application areas mainly involve Metros, street, temples, railway station and

other crowded areas.

Fig – 6.1 Applications

CHAPTER

NO.7

7.1

ADVANTAGES

·Power

generation is strolling on the step.

· No need for fuel input.

· This is the non-ordinary technique for

producing Power.

No

moving parts - long administration life.

· Self-producing-no outside power required.

· The system is reduced yet exceedingly touchy.

· It is Reliable, Economical, and Eco-Friendly.

· Less utilization of Non-sustainable power

sources

· Power is likewise produced by running or

practicing on the progression.

·Extremely

wide powerful range, free of commotion.

·No

big industries required for generation.

·Very

high-frequency response.

·Simple

to use as they have small dimensions and large measuring range.

7.2DISADVANTAGES

· The initial cost of this arrangement is

high.

· Care ought to

be taken for batteries.

· It isn't

reasonable for estimation in static conditions.

· It is not

suitable for measurement in static conditions.

· Since the

device operates with a small electric charge, they need high impedance cable

for electrical interface.

· The output may

vary according to the temperature variation of the crystal.

CHAPTER

NO.9

9.

CONCLUSION

The

project undertaken is effectively tried and actualized which is the best

conservative, reasonable vitality answer for average citizens of our country.

This can be utilized for some applications in rustic zones where control

accessibility is less or thoroughly truant .As India is a creating nation where

vitality administration is a major test for the gigantic populace. It is able

to extend this project by using same arrangement and construct in the

footsteps/speed breaker so that increase the power production rate by in fixing

school and colleges, highways etc. By utilizing this task we can drive both

A.C. and besides, D.C loads as indicated by the power we connected on the

piezoelectric sensor. This technique gives an effective power generation in

very populated nations as it diminishes control request without contamination.

As a reality, just 11% of sustainable power source adds to our essential

vitality. On the off chance that this undertaking is sent at that point not

just, we can conquer the vitality emergency issue yet, besides make a solid

worldwide ecological change.

9.1 FUTURE SCOPE-

The utilization of

wasted energy is very much relevant and important for highly populated

countries in the world in the future.

1. Flooring Tiles

Japan has already

started experimenting with the use of the piezoelectric effect impact on

generating energy. They implement a piezoelectric effect on the bus stairs.

Thus every time passenger steps on the tiles; they trigger the small vibration

that can be stored as energy in the battery. The flooring tiles are designed by

the rubber which can absorb the vibration. This vibration generates when people

are running or walking on it. Under these tiles, the piezoelectric material is

placed. They can generate electricity when the movement is felt by the

material. Simultaneously this generated energy is stored into the battery. The

generated electricity can be used for the lighting of a lamp or street light.

Energy is generated by the step of one human being is too less but if the number

of steps increases ultimately energy production also increases simultaneously.

2. Dance floors

Europe is one of the

countries which implemented and started experimenting with the use of a

piezoelectric crystal for energy generation in night clubs. The floor is then

compressed by the dancer's feet and piezoelectric materials make contact and

generate electricity which can be used as the generator in the club. The

generated electricity is nothing but 220 watts. It depends on the impact of the

dancer's feet. If constant compression of the piezoelectric crystal causes a

huge amount of energy.

3. The piezoelectric

crystals have being start better use with positive result. In India, maximum

public movement is observed in Railway stations, temples, and shopping malls;

hence this places can be used for piezoelectric crystals for generation of

electric power. Apart from all the above places a attempts are made to develop

energy from our daily life by initialing piezoelectric crystals in shoe thus in each step pie-zoelectric

crystal can be compressed which can turn enough power to charge a cell phone,

mp3 player etc.

1.

Prabaharan R, Jayramaprakash A, Vijay Anand. “Power Harvesting by Using Human

Foot Step”- International Journal of Innovative Research in Science Engineering

and Technology, vol.2, issue 7, July 2013.

2. Ramesh Raja R, Sherin Mathew.”Power

Generation from Staircase (steps)”- International Journal of Innovative

Research in Science Engineering and Technology, vol.3, Issue 1, February 2014.

3. Power Generation Using Foot Step Method.

4.

Itika Tandon, Alok Kumar. ”A Unique Step towards Generation of Electricity via

New Methodology”- International Journal of Advanced Research in Computer and

Communication Engineering, vol.3, Issue 10, October 2014.

5. Kiran Boby, Aleena Paul K, Anumol. C.V,

Josie Ann Thomas, Nimisha K.K." Footstep Power Generation Using

Piezoelectric Transducer”- International Journal of Engineering and Innovative

Technology, vol.3, Issue 10, April 2014.

6.

Footstep Energy Generation By Piezoelectric Effect: A Case Study On New Delhi

RailWay Station, International Journal of electronics & data communication.

7. Foot Step Power Generation Using

Piezoelectric Material, MathaneNitashree V., SalunkheArati L, GaikwadSayali S,

International Journal of Advanced Research in Electronics and Communication

Engineering (IJARECE) Volume 4, Issue 10, October 2015.

8.

Footstep Power Generation Using Piezo Electric Transducers, KiranBoby, Aleena

Paul K, Anumol.C.V, Josnie Ann Thomas, Nimisha K.K., International Journal of

Engineering and Innovative Technology (IJEIT) Volume 3, Issue 10, April 2014

9. Proposed Method of Foot Step Power

Generation Using Piezo Electric Sensor, Mr.A.Adhithan1, K.Vignesh,

M.Manikandan, International Advanced Research Journal in Science, Engineering

and TechnologyVol. 2, Issue 4, April 2015.

Comments

Post a Comment